Mastering Rapid Prototyping Manufacturing: An Essential Guide for Metal Fabricators

Rapid prototyping manufacturing is transforming the landscape of product development, empowering metal fabricators to bring their ideas to life more swiftly and efficiently than ever before. In this comprehensive guide, we will delve into the intricacies of rapid prototyping, explore its various methods, and examine how it is shaping the future of the manufacturing industry.

Understanding Rapid Prototyping Manufacturing

At its core, rapid prototyping manufacturing involves the quick fabrication of a scale model or a prototype of a physical part or assembly using three-dimensional computer-aided design (CAD) data. This process allows designers and engineers to iterate on their designs quickly, ensuring that errors are caught early and allowing for adjustments before full-scale production begins.

The Importance of Rapid Prototyping

In today’s fast-paced market, speed and agility are vital. Companies that can swiftly bring products to market have a distinct competitive advantage. Here are some reasons why rapid prototyping is crucial:

- Accelerated Product Development: Rapid prototyping significantly shortens the time needed for product development, enabling businesses to innovate faster.

- Cost Efficiency: By identifying potential design issues early, companies can save on production costs and time.

- Improved Design Quality: Prototyping allows for continuous feedback and refinement, leading to higher quality products.

- Greater Flexibility: Rapid prototyping invites experimentation, which can lead to more innovative solutions and designs.

Methods of Rapid Prototyping Manufacturing

There are several methods used in rapid prototyping manufacturing, each with its own set of advantages and applications. Below are the most commonly used techniques:

1. Stereolithography (SLA)

Stereolithography is one of the earliest 3D printing technologies. It uses a laser to cure liquid resin into hardened plastic, layer by layer. SLA produces high-precision prototypes with excellent surface finish.

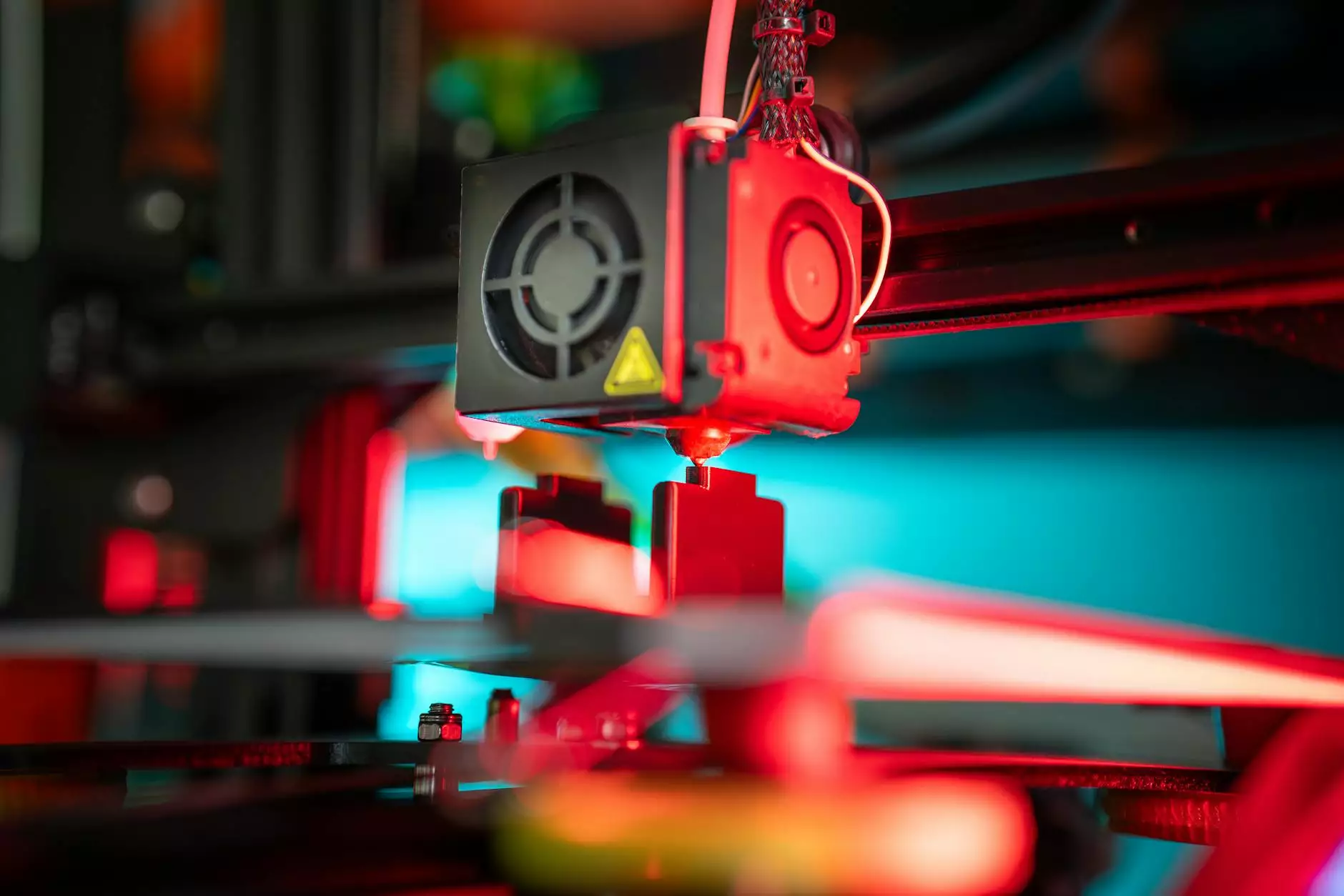

2. Fused Deposition Modeling (FDM)

FDM involves the extrusion of thermoplastic filaments through a heated nozzle. This method is widely used due to its affordability and versatility, making it ideal for functional prototypes.

3. Selective Laser Sintering (SLS)

SLS uses a laser to fuse powdered material, typically nylon or polymer resin, into a solid structure. This method is ideal for producing complex geometries and functional parts.

4. Digital Light Processing (DLP)

DLP technology employs a digital light projector to flash a single image of each layer across the entire build platform simultaneously. This leads to faster printing speeds compared to SLA.

5. Binder Jetting

This technique involves depositing a binding agent onto layers of powder, which are then cured to form solid parts. Binder jetting is particularly advantageous for metal parts, as it can produce dense and intricately designed components.

Applications of Rapid Prototyping Manufacturing in Metal Fabrication

Rapid prototyping has myriad applications within the metal fabrication sector. Its ability to produce accurate and durable prototypes is essential for various industries:

1. Automotive Industry

In the automotive sector, rapid prototyping is used to create parts for testing, design iterations, and tooling. It allows manufacturers to assess the feasibility and performance of new components before mass production.

2. Aerospace Sector

The aerospace industry heavily relies on rapid prototyping to produce complex geometries, reduce weight, and enhance performance. Prototypes can be developed for everything from cockpit controls to airframe components.

3. Medical Devices

In the medical field, rapid prototyping is invaluable for developing custom implants, surgical instruments, and prosthetics. The ability to produce personalized solutions quickly is a game changer for patient care.

4. Consumer Products

Rapid prototyping plays a critical role in designing and testing consumer products, allowing companies to gauge consumer reactions through working models before launching a product.

The Future of Rapid Prototyping Manufacturing

The future of rapid prototyping manufacturing is bright and full of potential. The integration of advanced technologies such as artificial intelligence (AI), machine learning, and enhanced materials will further streamline design and production processes. Here are a few upcoming trends:

1. Incorporation of AI and Automation

Using AI, manufacturers can optimize their designs and streamline the prototyping process. Automation will also enable faster production cycles and reduced human error.

2. Advancements in Materials

Innovative materials that are stronger, lighter, and more versatile will open new avenues for rapid prototyping. This can include composites and advanced metal alloys tailored for specific applications.

3. Increased Accessibility

As technology improves and costs decrease, access to rapid prototyping tools is expected to expand. This democratization will empower smaller businesses and individual entrepreneurs to innovate.

Conclusion

In summary, rapid prototyping manufacturing is not just a trend; it’s a significant advancement that is reshaping the future of metal fabrication and manufacturing as a whole. The advantages it offers in terms of speed, cost, and quality are unparalleled, and as technology evolves, its applications will only grow more impactful.

For metal fabricators looking to stay ahead of the competition, embracing rapid prototyping is not merely an option but a necessity. By understanding and leveraging this powerful tool, businesses can enhance their product offerings, improve design processes, and ultimately drive greater success in an ever-evolving marketplace.

For comprehensive solutions in metal fabrication and rapid prototyping, visit deepmould.net and discover how we can help you streamline your processes and achieve your design goals.